CNC Machine Components

Control system

- MITSUBISHI generally features a higher stability than Syntec. During programming, it will continue to operate according to the original settings, in case of emergency

- It is faster than Syntec.

- It rounds better than Syntec.

- FANUC is most often used in gantry.

- It is more stable than MITSUBISHI.

- FANUC has a larger torsion and cutting strength.

- It is fast.

- It carries out a better rounding.

- SIEMENS runs as fast as FANUC.

- Its tool line is better than FANUC.

- Its precision is higher than FANUC.

Tying CNC’s motor is paired well with the control system. With this excellent compatibility between the control system and the motor, a high precision is guaranteed.

GuidewayTying CNC machines usually use a linear guideway. However, in order to achieve a higher cutting force, some machines will use a box guideway, which are stated in the machine. Linear guideways are available in a roller or ball option. For customers that need to machine precision parts, we recommend a ball linear guideway, whereas a roller linear guideway is better for processing large precision components.

Spindle-

Gear spindle

Gear spindle -

Belt drive spindle

Belt drive spindle -

Direct drive spindle

Direct drive spindle

Tying CNC’s spindle equipment includes a mechanical spindle and an electric spindle. Electric spindles are used in CNC drilling and milling machine due to their high speed.

According to the installation structure, spindles are categorized into direct drive, belt drive, and gear drive spindles.

A direct drive is used in a CNC drilling center. However, when the spindle bears a higher force, then a belt drive spindle is used to avoid damage to the spindle motor. A gantry milling machine uses a gear drive, which allows for a large torque and allows for the greatest machine depth.

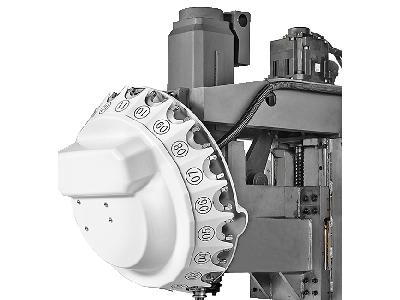

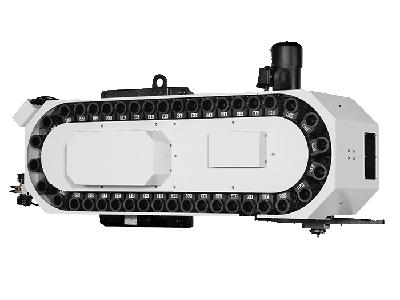

Tool storageTying CNC provides four tool magazine types: carousel, turntable, disc and chain.

Carousel-type tool magazines are generally installed on CNC milling and drilling machine, which requires less tools. This particular tool magazine can hold 12 tools.

The Turntable type tool magazine is specially designed for vertical CNC machining centers. It equips the mechanical arm to prepare tools, which enhances the processing speed. This tool magazine can hold 24 tools.

The disc type tool magazine is mainly used in CNC drilling machines, and is capable of holding 16 tools at a time.

Dongguan Tying CNC Machine Tools Co., Ltd.

Add.: No.5, Jinfu 2nd Road, South China Industrial, LiaoBu Town, Dongguan City, Guangdong Province

Contact: Peter

Tel: +86-769-83030195

Fax:+86-769-85789126