- Home

- Applications

- Large Components CNC Machining

Most common CNC machining equipment is suitable for the machining of workpieces with a size range within 1m. If you need to machine large components with sizes exceeding 1m, then you will require a CNC machining center with a large workbench or gantry machining center.

When machining large components, clamping and loading capacity are typically the most important factors to take into consideration. When designing CNC machines, Tying CNC tends to increase the machine weight or adopt an open structure with a gantry machining center. This method makes it convenient to lift the workpiece to the worktable. According to the hardness of the machined materials, the structures of the spindle and workbench will also differ. If you want to process steel materials with greater hardness, we recommend a machining center with 3-axis box guideways. If you will be working with a variety of materials, a machining center with X/Y-axis linear guideways and Z-axis box guideway would be more suitable as they offer greater flexibility.

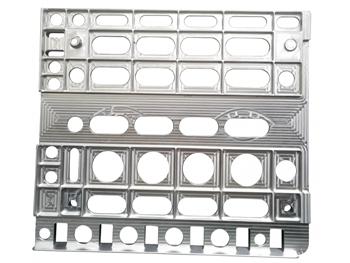

The following are some of the large components for automotive and ship produciton machined by customers with our machines: Recommended equipmentPrecision CNC Metal MachiningThe requirements for dimensional tolerance are very strict in some precision machining industries for products like watches, eyeglasses, gears and so on. For stainless steel, carbon steel

Read MoreDie and Mold MakingDie and mold production is a sophisticated process and if you need to produce high-quality molds, you will also need high precision machining equipment. Typically, molds are made from die steel

Read MoreMetal Parts CNC MachiningMetal parts produced using aluminum alloy, stainless steel, copper, zinc alloy, and other materials are found in almost all the vital equipment we use every day. Our phones, our cars, our bikes

Read More